Scope of application

Silicon PU healthy professional flexible court material is suitable for all kinds of basketball, tennis, badminton, table tennis, volleyball, handball and other indoor and outdoor courts, indoor small football field, various fitness rooms, activity rooms, various sports venues and kindergartens.

Guarantee /Applicable life : 10 years

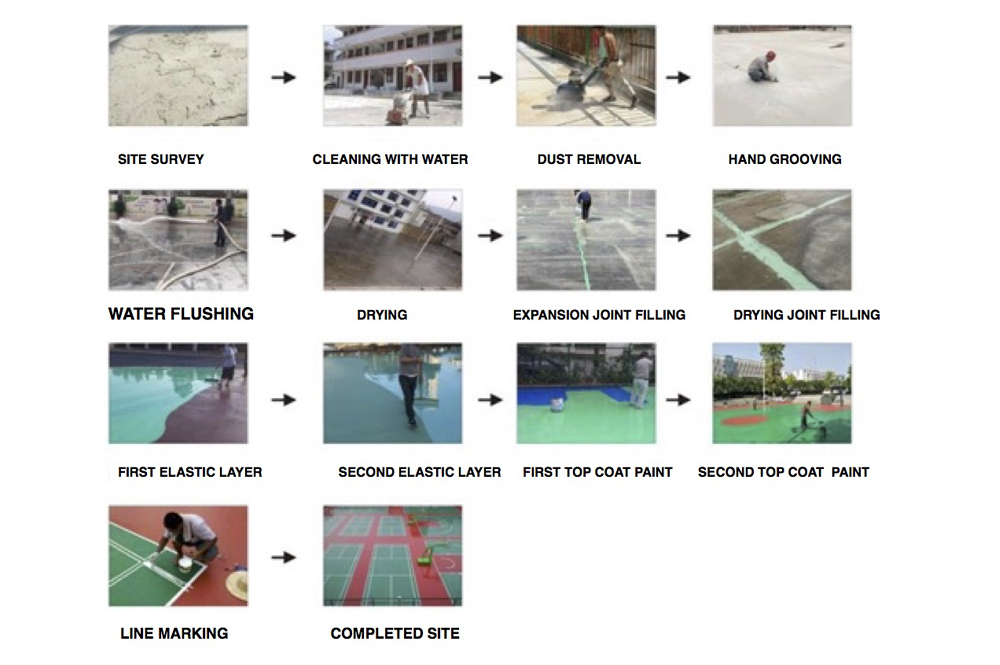

Environmental Protection Silicon PU Construction Process Treatment of Temperature Joint in Cement Concrete Foundation Reasonable temperature expansion joints must be cut after casting of new cement foundation. The principle is that a standard basketball court or a standard tennis court only needs transverse midline and two bottom lines cut three temperature expansion joints without cutting in longitudinal direction. Temperature lines must be cut between casting construction plates.

The width of temperature line is 5-8 mm and the depth of the joints is not less than 20 mm (the depth of the joints is mixed). Two-thirds of the condensate foundation is suitable to ensure that the thermal expansion and contraction energy of the foundation concentrates in the temperature crack and does not lead to cracking in other parts of the foundation.

After the foundation is dried, a professional one-component waterproof primer is applied to both sides of the temperature crack, and then the sealant material is poured into the temperature crack. The best effect is that the seam surface is slightly smaller than that of the seam after filling. Shallow 2-3 mm, in order to reduce the influence of thermal expansion and contraction of foundation on the extrusion deformation of filling material and the surface effect, expose the part of the base surface and smooth the base surface with a hand-held grinder, lay a thinner site (such as 3 mm thick), must be ground at 40-50 mm twice, each of the base surface must be lowered by 1.5-2.0 mm before filling treatment, in order to ensure the evenness after laying.

Paving Technology of Silicon PU Material

Waterproof Bottom Layer

If it is an old cement foundation, damaged, evergreen moss, bumps and other phenomena, the ground should be cleaned and cleaned by sanding surface, if it is a new cement foundation, it should be maintained and cleaned, or see the effect of basic maintenance can be diluted with hydrochloric acid or oxalic acid to wash the site, after drying, the waterproof primer should be brushed on the drum. The ground should be checked twice and carefully. There should be no uncoated area.

Dayal Silicon PU Elastic Layer Laying method

Silicon Pu elastic layer is a single component. Before construction, the elastic layer is carefully checked to confirm that the foundation treatment is completed before the elastic layer construction. Silicon PU elastic material is stirred evenly at high speed. The material is directly coated and scraped with plywood layer by layer on the base. The amount of material to be paved is calculated during construction, and the materials is stirred and unpacked paved quickly. Otherwise, it will solidify waste materials. The time interval of each layer is the first layer of dry solidification. The specific dry solidification time depends on the weather conditions on site. The thickness of each layer is recommended to be 1-1.5mm or so until the required thickness is reached 4mm . levelled when scraping to ensure surface smoothness. Construction in hot sun and high temperature is avoided. After the elastic layer is dried and solidified, surface smoothness should is by water accumulation method.

Dayal Silicon PU Top coat

Silicon PU water-borne topcoat is constructed by mixing color paste and curing agent evenly according to the proportion. It is scraped and coated on the surface of elastic layer three times with spray gun or drum. For example, the friction coefficient can be adjusted by surface rake, and the special quartz sand for surface layer can be added to mix evenly and then scraped.we avoid construction in hot sun and high surface temperature.

Volley Ball/Basket ball/Badminton/Tennis/sports Course marking

Positioning according to standard size, marking the position of the boundary line, placing it on the court along both sides of the boundary line with beautified paper, painting it between beautified paper with special marking paint, and brushing it in two ways. If the surface of the court is rough, the first one can be added with a little special sand coating to prevent seepage, because our company's marking material is water-based aliphatic marking. Liner paint (not fading and yellowing, full texture), so after finishing painting, tear off the paper after the surface is dry.